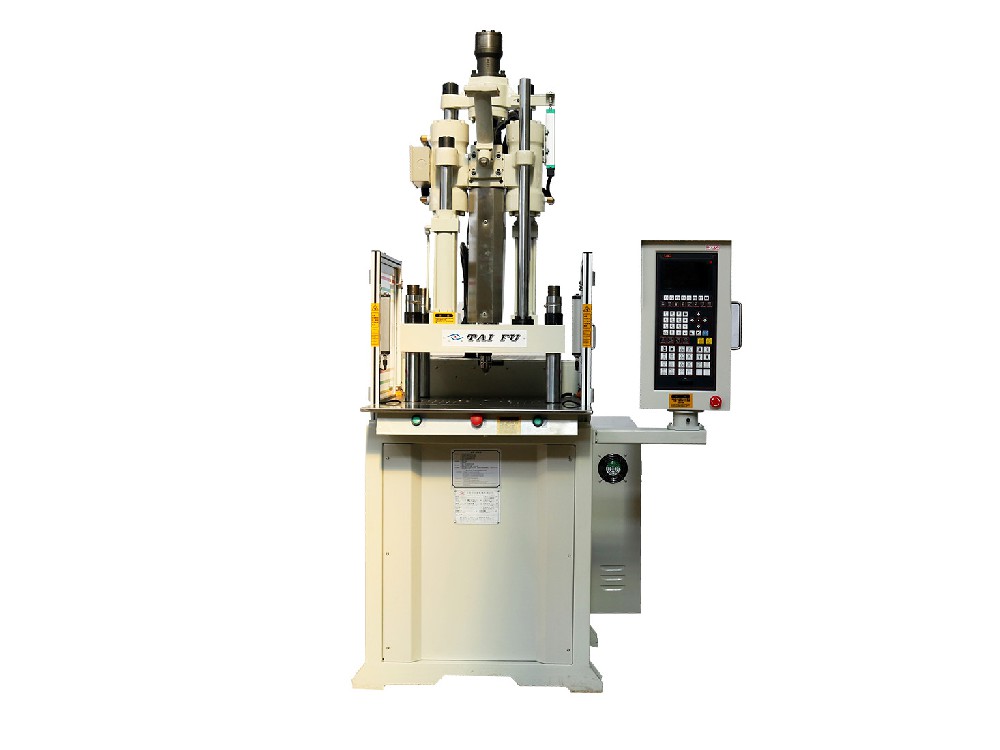

立式标准注塑机4

产品介绍

立式橡胶注塑机是一种专门用于橡胶材料注塑成型的机械设备,它具有以下特点:

1. 注射装置与锁模装置在同一垂直中心线上,这样设计可以减少占地面积,同时便于模具的开闭和维护。

2. 模具沿上下方向开闭,这样的设计有利于嵌件成型,因为模具表面朝上,嵌件可以更容易地放入定位。

3. 占地面积小,立式注塑机的占地面积通常只有卧式注塑机的一半左右,这使得它在空间有限的生产环境中更加适用。

4. 易于实现自动化,立式注塑机的开放式设计使得它可以更容易地配置各种自动化装置,适应复杂、精巧产品的自动成型。

5. 模具重量由水平模板支撑,这样的设计可以避免模具因自重而发生前倾,有利于保持机械和模具的精密度。

6. 注射压力大,立式注塑机通常配备大扭矩液压马达,能够提供强大的注射压力,确保橡胶材料能够充分填充模具型腔。

7. 多段压力输出,立式注塑机能够提供多段压力输出,以适应不同类型的橡胶材料和成型要求。

8. 适合大射胶量生产,立式注塑机适合生产大型橡胶制品,因为它能够提供足够的注射量和压力。

这些特点使得立式橡胶注塑机在橡胶制品的生产中具有高效率和高精度的优势,广泛应用于汽车、电子、医疗等领域。

Vertical rubber injection molding machine is a kind of machinery and equipment specially used for injection molding of rubber materials, which has the following features:

1. the injection device and the clamping device are on the same vertical centerline, this design can reduce the floor space, and at the same time, it is easy to open and close the mold and maintenance.

2. the mold opens and closes in the up and down direction, this design is conducive to insert molding, because the mold surface is facing up, the insert can be more easily put into position.

3. small footprint, the footprint of a vertical injection molding machine is usually about half that of a horizontal injection molding machine, which makes it more suitable for production environments where space is limited.

4. easy to realize automation, vertical injection molding machine's open design makes it easier to configure a variety of automation devices, adapt to complex, delicate products automatic molding.

5. the weight of the mold is supported by the horizontal template, this design can avoid the mold from tilting forward due to its own weight, which is conducive to maintaining the precision of the machinery and mold.

6. High injection pressure, vertical injection molding machines are usually equipped with high torque hydraulic motors, which can provide strong injection pressure to ensure that the rubber material can fully fill the mold cavity.

7. Multi-stage pressure output, vertical injection molding machine can provide multi-stage pressure output to adapt to different types of rubber materials and molding requirements.

8. Suitable for large injection volume production, the vertical injection molding machine is suitable for producing large rubber products as it can provide sufficient injection volume and pressure.

These features make the vertical rubber injection molding machine have the advantages of high efficiency and high precision in the production of rubber products, which are widely used in automotive, electronics, medical and other fields.